LDS technology principle

Concept explanation: The meaning of “LDS” : LDS = Laser-Direct-Structuring

It is that selectively chemical plating on the plastic substrate for metallization by laser direct forming process.

Usually requires 3~4 process steps

• Injection molding • Laser activation •Chemical plating / Metallization •SMT Assembly(optional)

Injection molding Laser activation Chemical plating Cu Chemical plating Ni/Gold

The main application of LDS technology:

LDS technology in America, Japan, Europe and other developed countries and regions have been widely used in communications, automotive electronics, computers, electrical and mechanical equipment, medical equipment and other industries. Currently the most mature application areas are wireless communications products, mainly for the smart phone antenna. Mainstream smart phone manufacturers most models have used the LDS- MID antenna.

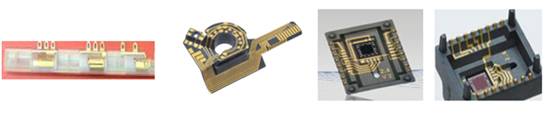

Notebook Circuit board Bracket Sensor

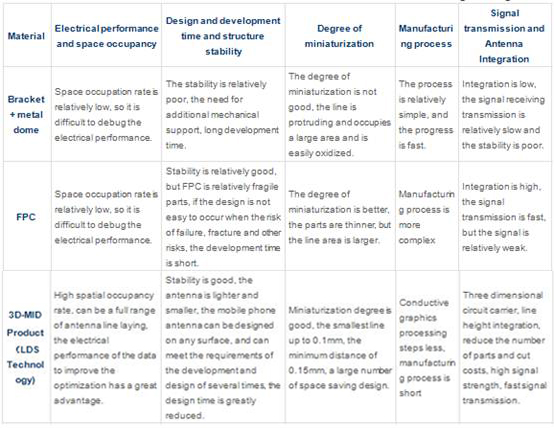

The application advantages of LDS materials in the antenna field:

Sinoplast LDS solution

Sinoplast LDS special material technology has applied to the naitonal patent protection. We are the first domestic enterprises to get the German LPKF authorization. The material is good fluidity, easily molding, good dimensional stability and chemical resistance etc..

LDS material application examples

Mobile phone antenna medical apparatus and instruments

Wireless network card steering wheel

LDS common problems and Actions

Dislocation, Dimension error

Reasons: 1. Wrong laser etching program; 2.Product deformation, tolerance is too large or too small, cause not laser etched in the set position.

Actions: 1. Check the laser program, especially whether the joint position is completely butt joint or not ; 2. Products are maintained within the specified tolerance, and ensure the product can not be deformed during

Transportation.

Cannot plating, skip plating

Reasons: 1. Laser energy is not enough; 2. Laser energy is too high to cause pattern position burning; 3. Chemical plating solution is not active enough; 4.Material problem; 5. Added gate material; 6. Use wrong material, mixed material;

Actions: 1. Use proper laser energy; 2. Adjust plating solution activity; 3. use market test OK and get the LPKF authorization material; 4. Forbidden to add any gate material; 5. strengthen workshop management to eliminate using mixed or wrong material.

Over plating

Reasons: 1. After laser etching does not clean dust; 2.Not doing ultrasonic clean before chemical plating; 3. Chemical plating solution activity is too high; 4. Antenna design is not reasonable, the line is too narrow or too close to the edge, protrusion.

Actions: 1. Control process, clean the dust after laser etching; 2. Ultrasonic clean before plating; 3. Adjust activity of the chemical plating solution; 4. Antenna design should avoid the steps, rib ect. or at least to maintain the 0.3mm distance, the line distance should be greater than 0.4mm to ensure stable production.

Scratch, bump on antenna

Reasons: 1. Use roll plating; 2. After chemical plating use dry method; 3. Operator scratch antenna and plastic parts during over plating dealing.

Actions: 1. As far as possible to use rack plating or use some methods to protect product during roll plating; 2.Avoid to use drying methods, should use hot air drying; 3. Control over plating to avoid man-made scratch.

Sinoplast LDS Material processing matters needing attention

Temperature

Dry conditions: setting based on different materials, see the above table, recommend dehumidifying dryer.

Mold temperature: setting based on different materials, see the table (the actual temperature).

Molding temperature: the molding temperature of LDS substrate materials is lower than ordinary, should be set according to different materials, see the above table.

Back pressure: it is recommended to control within 2~6Mpa.

LDS material storage

Store in a cool, dry place to avoid sun exposure, humidity should be controlled within 60%. As far as possible store the whole package, if there is a packet must be sealed again, more than 24 hours suggest to scrap.

Cannot add any gate materials for production.

Need to use plastic bags for packaging when transfer, will affect the laser plating if absorb moisture.